In November 2018, GE Healthcare opened a manufacturing centre in Stevenage, UK. The facility is scheduled to open for commercial operations in the first half of 2019.

The plant will manufacture products based on GE’s fibre-based purification platform, FibroSelect. It is expected to increase the company’s manufacturing efficiency of products such as biopharmaceuticals, gene therapies and viral vectors.

Once operational, a total of 20 people will be employed at GE Healthcare’s biotechnology manufacturing centre.

Location of GE Healthcare’s Stevenage centre

The facility is located in the Stevenage Bioscience Catalyst (SBC) Open Innovation Campus, 30 miles (48km) away from London.

SBC is the UK’s first open innovation campus established by a joint venture (JV) of the UK Government’s Department for Business, Innovation and Skills (defunct as of July 2016) alongside pharmaceutical company GlaxoSmithKline, health research charity Wellcome and non-departmental public body Innovate UK.

The innovation campus makes equipment and facilities accessible to small or medium-sized companies.

GE Healthcare’s Stevenage centre details

The biotechnology manufacturing centre will feature 3,000ft² (280m²) of cleanroom space containing bioprocessing equipment.

The fibre-based chromatography technology for purification used at the facility was added to GE Healthcare’s portfolio following the company’s acquisition of Puridify, a spin-out from the University College London (UCL). Puridify is also located in SBC in Stevenage.

The FibroSelect purification technology will allow for the incorporation of novel processing strategies. It will enhance the productivity of biopharmaceuticals such as monoclonal antibodies with high purification.

The technology will be used to improve the process flexibility and efficiency to meet the growing demands of the industry. The product manufacturing will support the company’s entire spectrum of bioprocess purification portfolio.

The fibre-based purification products manufactured at the facility will be further processed and finished at GE’s existing manufacturing facility in Cardiff, Wales.

GE also plans to produce products serving laboratory and clinical applications in the future.

Details of the FibroSelect process technology

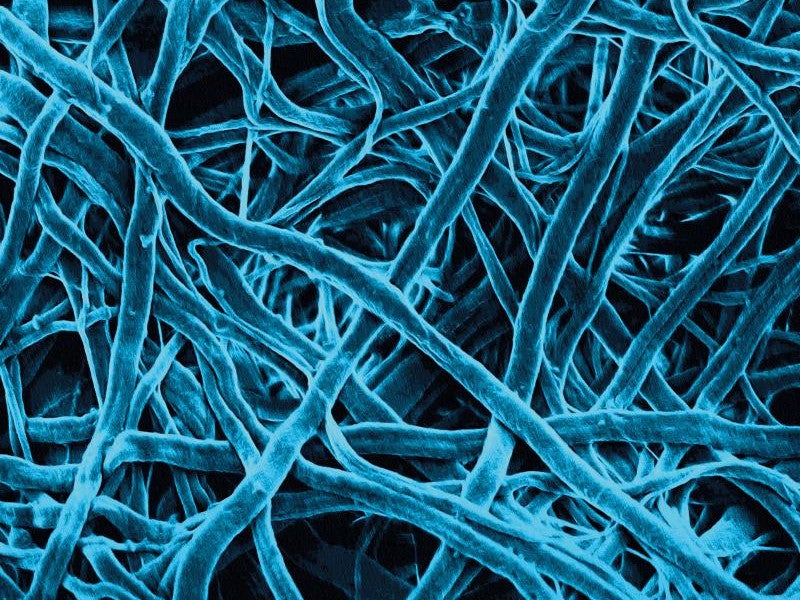

The FibroSelect technology uses a material that features a new proprietary structure, which avoids the limitations of diffusion and flow related to conventional chromatography purification systems. It also resolves capacity-related issues posed by chromatography membranes.

The technology also overcomes issues related to predicting scaled performance in robust process due to the fixed nature of the material. The technology’s macroporosity enhances the purification process for biotherapeutics such as gene therapies and fusion proteins.

The FibroSelect technology’s optical permeability and mass transfer properties enable it to operate at 50 times throughput and improve productivity by ten to 50 times. The reagent is said to perform better than existing products on the market in terms of impurity and cleaning steps.

The FibroSelect includes new tools and automated platforms that can improve research performance and process scales. It also reduces bioprocess development timelines and improves predictable performance and process robustness.

Market commentary on GE Healthcare

GE Healthcare is a subsidiary of US-based conglomerate General Electric Company. The company provides a range of technologies for medical imaging, monitoring, drug development and manufacturing to provide precision health technologies and therapeutics.

The company, which employs more than 50,000 people worldwide, also develops smart devices for data analytics.