SAFC, a business unit of Sigma-Aldrich Corporation, opened a dry powder media (DPM) plant at its manufacturing facility in Irvine, Scotland, in January 2015.

The expansion adds dry powder milling and blending capabilities to the Irvine plant, which is an established centre for manufacturing liquid media, buffers and reagents for the biopharmaceutical industry.

In addition, the facility features dry powder cell culture media to produce large-scale bulk dry powder media and reagents. It is designed to cater to the growing biopharmaceutical industry in the European and Asia-Pacific markets.

The validated plant now serves as the European counterpart to SAFC’s centre of excellence for dry powder media and reagent manufacturing in Lenexa, Kansas.

Facilities and technology at the dry powder media manufacturing plant in Scotland

The state-of-art DPM manufacturing facility features warehouses with temperature-controlled storage areas for raw material and finished goods. Warehouses will be continuously monitored using a facility monitoring system.

The facility includes new formulation suites with humidity control designed to support product lot formulation from small to large scale. Rooms will be continuously monitored for efficient operation.

All the plant’s process rooms are controlled environmentally and have dedicated heating, ventilation and air conditioning (HVAC) systems where appropriate.

All equipment holds validated cleaning processes, including clean-in-place processes for fixed equipment and pipework, clean-out-of-place processes for washrooms, and an automated intermediate bulk container washer.

The facility also features a purified water plant and distribution loop producing European and US Pharmacopoeia-grade water. Clean, compressed air and clean nitrogen will be supplied and distributed throughout the plant.

The plant’s manufacturing facilities, processes and technology are similar to those at the Lenexa facility to ensure consistency in production quality at both sites.

The entire construction work at the facility complies with US Food and Drug Administration (FDA) and EU current good manufacturing practice (cGMP) regulations, as well as local safety and environmental regulations.

Production at the DPM manufacturing plant in Irvine, Scotland

The plant produces animal component-free (ACF) media complementary to the liquid cell culture media, buffers and reagents already being produced at the site.

In addition, the plant features two separate manufacturing lines. The first line is a pin-type mill with a conical, auger screw pre-blender and tumble post-blender, capable of producing ACF dry powder media batches ranging from 750kg to 6,000kg.

The second line is also a pin-type mill with tumble pre and post-blenders, capable of manufacturing dry powder media batches ranging from 25kg to 750kg.

Details of the SAFC centre of excellence in Irvine

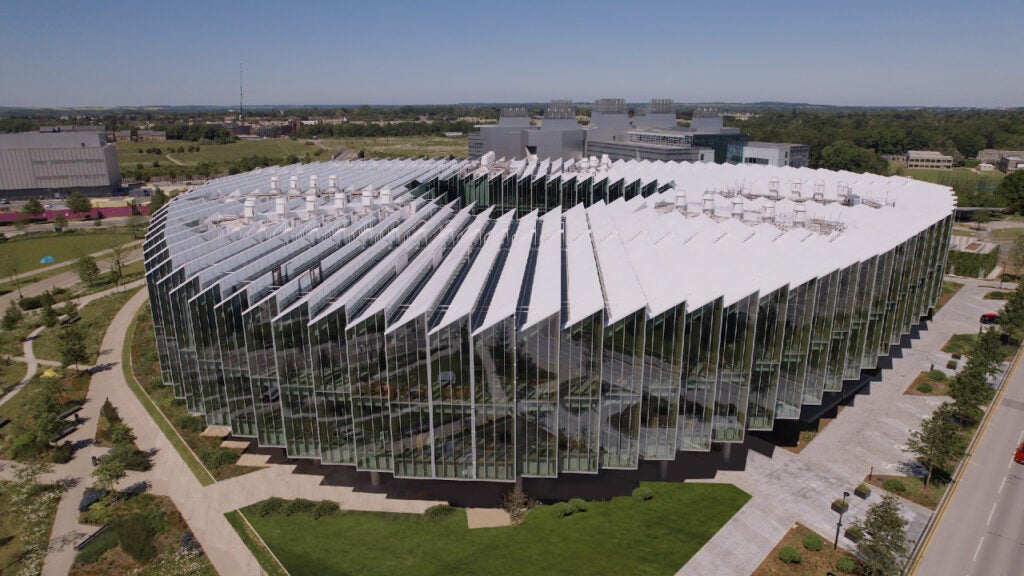

SAFC’s Irvine facility is an 11,000m² cGMP manufacturing facility featuring liquid production facilities, quality control laboratories and temperature-controlled warehouses.

Core technologies at the plant include automatic aseptic filling of bottles and bags, validated steam-in-place, clean-in-place and flexible manufacturing systems, as well as disposable systems and a wide range of testing capabilities for raw materials and finished goods.

The plant manufactures custom and catalogue formulations, liquid media, reagents and downstream purification buffers of pack sizes from 5ml to 500l, as well as batch sizes up to 10,000l (bags) and 6,000l (bottles).

Marketing commentary on SAFC

SAFC provides products and services for use in regulated pharmaceutical and biopharmaceutical applications. The company is claimed to be one of the world’s top ten chemical and biologics suppliers.

The company’s product portfolio includes high-purity inorganic materials for high technology applications, raw materials and biologics safety testing services for biopharmaceutical manufacturing, and high-potent active pharmaceutical ingredients (APIs) and key intermediates for pharmaceutical manufacturing.