Dividella develops secondary pharmaceutical packaging solutions and systems for vials, ampoules, syringes, pens, combination packs, medical devices, blisters, and many more medical products.

Customers in pharmaceutical and biotech companies benefit from extensive engineering support. The company’s specialists find dependable solutions for the safe packaging of sensitive products, optimised pack sizes for the cold chain, and easy-to-use mono material packaging with a low total cost of ownership.

With more than 30 years of experience in packaging and machine development, Dividella’s solutions are sustainable thanks to their unique modularity.

High-quality cartons for the storage and transportation of pharmaceutical products

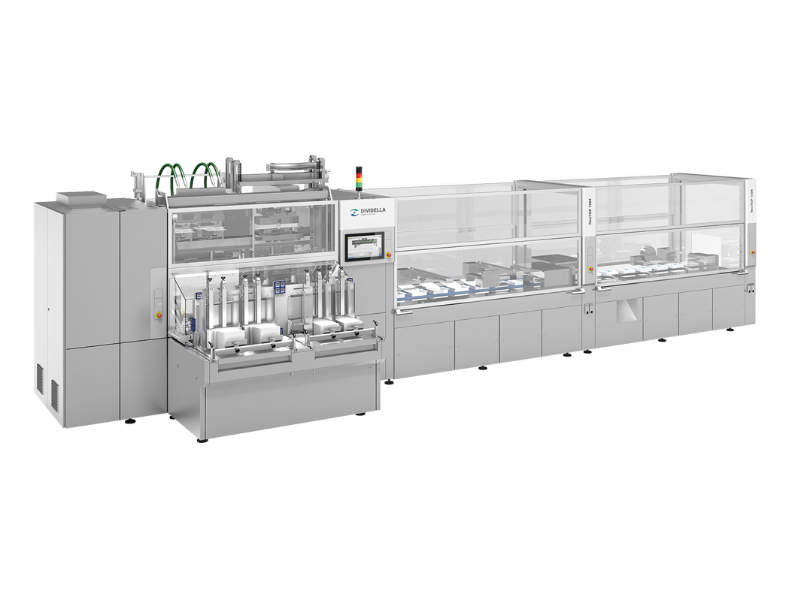

Dividella’s packaging process begins with toploading box erection. Using the rotor principle, the company’s machines achieve a consistent high-performance and high-quality carton. Once set up from flat carton and partition blanks, the carton is placed on a vacuum conveyor system and is moved through the machine.

Various other proprietary systems such as cameras, inspection, Track &Trace components, and marking systems can be integrated into the machine without any problems.

Fast small-batch pharmaceutical packaging production

Small-quantity packaging production is often needed for applications such as clinical trials, market launches, and market research. It is also often the case that the manufacturer does not have suitable production lines for such a small amount, meaning potential waste and overproduction.

Dividella’s small-batch pharmaceutical packaging production offers a solution, with quick-time-to-market production. All styles of packaging can be produced on Dividella’s flexible and adaptable packaging system NeoTOP, whether for clinical trials or establishing a market presence. For the smallest batch size, the company’s modern facilities can be used for all processes, from plotting, to printing and erecting.

Individually selected product packaging production lines

Dividella implements a customer-orientated service, with a top priority to discover the optimal packaging solution for any client. A suitable machine is chosen from the range, decided by production volume and batch size.

The packaging systems are designed with high attention to detail. Each machine is accurate and optimised for various load sizes. The Neo TOP handles smaller to medium-sized lots, whereas the Neo TOP 804 is designed for medium to large-sized lots.

Dividella’s machines are modular, meaning increased flexibility. An almost unlimited number of packaging can be processed, whether the pharmaceutical product to be packaged is inclusive of a blister, de-nester, thermoformer, or magazine.

Flexible feeding systems for parenterals

Dividella presents a variety of feeding technologies for parenterals. Its wide and flexible range are scalable and customised to assist the packaging of up to 500 objects per feeding unit. Products can be aligned, spread, and individually checked before insertion and linking to upstream machines.

Use of Parenteral Packaging and the latest trends

Users of Dividella’s equipment return time and time again to adapt their existing system or to acquire new lines. The company manufactures quality, easily modifiable, easy-to-use and excellently serviced equipment, which is tailored to the individual needs of the client.

Significant changes have been seen in the packaging of parenterals over the past few years worldwide. However, when speaking of worldwide trends the sustained growth in oncopathology patients and the prevalence of cardiovascular disease and diseases of the respiratory system must be noted.

The parenteral drug segment accounts for 30% of the overall global market of dosage forms. Nearly half of the medicines in this segment are biopharmaceuticals, at 47%. Small molecule inhibitors make up 38%, which in turn consists of 24% preparations for the treatment of oncopathology patients, 20% antibiotics and anti-bacterial agents, and 5% drugs for the treatment of patients with blood disorders. The other 45% consist of medicines for treatment of other illnesses. The vaccine market accounts for 5% of the overall market of parenteral drugs.