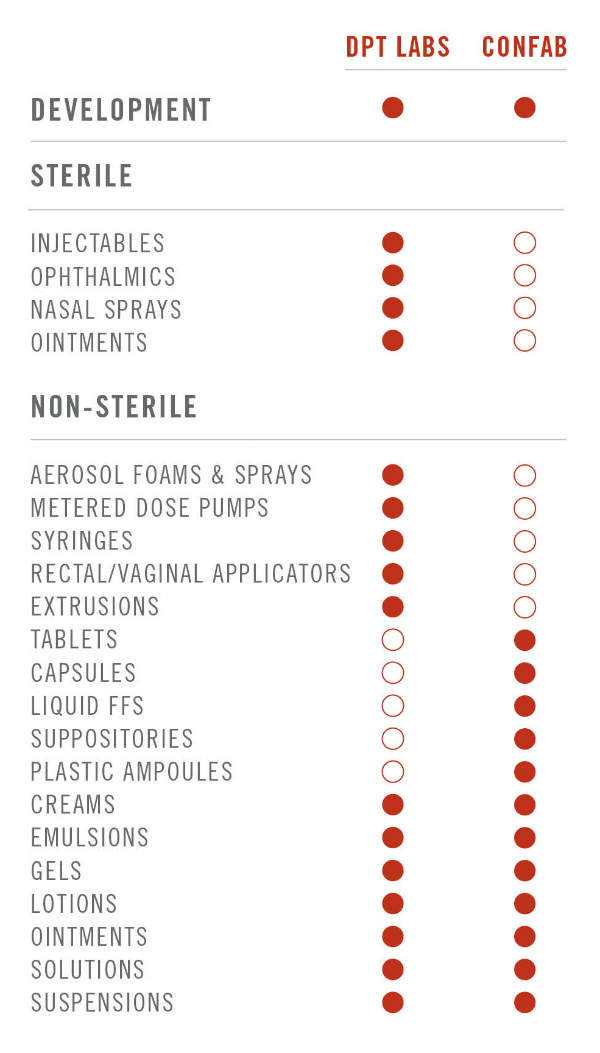

DPT and Confab are part of Renaissance Acquisition Holdings’ portfolio of companies. Together DPT, and Confab offer a broader range of services with complementary manufacturing capabilities, expertise in product development, technical transfers and scale-up. We provide the ability to manufacture a wide range of products across multiple dosage forms and world-wide distribution.

DPT is a contract development and manufacturing organization (CDMO) that specializes in semi-solids and liquids. DPT offers unmatched technical expertise and fully integrated drug development and manufacturing services for sterile and non-sterile dosage forms.

From Non-Serile to Sterile,

From Concept to Commercialization,

From Virtual to Large Pharma.

Confab, a DPT Company, is a fully integrated CDMO. Our key focus and expertise is in the development and manufacturing of complex solid dose, semi-solid creams and suppositories and liquid products.

Partnering with DPT and Confab provides a seamless transition from pre-formulation and formulation development through to clinical supplies and commercial supply. Together, we are known in the industry for providing dependable high quality services to customers worldwide and for sharing success and growth with our partners and employees.

Development services

DPT provides comprehensive pharmaceutical research and development services focused on non-sterile and sterile semi-solid and liquid dosage forms.

Confab provides comprehensive pharmaceutical research and development services focused on immediate and sustained release solid, semi-solid, and liquid dosage forms.

Together, DPT and Confab offer complimentary manufacturing capabilities with expertise in product development, technical transfers and scale-up. Our scientists combine decades of pharmaceutical formulation development expertise with leading-edge technologies to provide the best solutions to our customers’ needs.

Pharmaceutical research and development services

Our pharmaceutical research and development services include:

- Pre-formulation

- Formulation development

- Analytical development

- Analytical validation

- Drug packaging services

- Process development

- Stability studies

- Microbiology

- Clinical trial materials

- Regulatory submission support

- Inhalation product testing

Non-sterile and sterile pharmaceutical research and development expertise

Our expertise in research and development non-sterile and sterile items include:

- Tablets

- Capsules

- Liquid FFS

- Suppositories

- Plastic ampoules

- Aerosol formulations

- Creams

- Extrusions

- Foams

- Gels

- Liquids

- Lotions

- Ointments

- Ophthalmics

- Otics

- Nasal sprays

- Solutions

- Suspensions

Semi-solids and liquids

DPT’s Center of Excellence for Semi-solids and Liquids is supported by in-house quality and microbiology labs, robust quality systems and a team of highly skilled technicians to support your manufacturing needs.

Semi-solid and liquid pharmaceutical manufacturing services

Our services for manufacturing of semi-solid and liquid pharmaceutical products include:

- Pilot, clinical trial material and commercial-scale manufacturing

- cGMP batch sizes from 0.3kg to 25,000kg

- Compartmentalized, controlled environment and XP compounding

- Controlled substances schedule II – V

- Extensive range of vessel, dissolver and mixing options

- Vacuum pressure capabilities

- Nitrogen / inert gas blanketing

- Direct-to-line packaging

- HEPA air filtration and improved air handling

- Wide range of lighting options for light-sensitive materials

- Semi-solid and liquid packaging capabilities

- Advanced barrier systems

- Airless and metered-dose pump system

- Bottles

- Jars

- Metal and laminate tubes

- Piston barrier systems

- Pouches

- Rectal and vaginal applicators

- Syringes: large format and dial dose

- Thermo and cold-form blisters for liquids and semi-solids

- Unique and specialized pharmaceutical packaging

- Virtually any secondary packaging required

Aseptic manufacturing services

Aseptic manufacturing services include:

- Aseptic processing and filling suites for small volume parenterals, ophthalmic preparations, nasal sprays and ointments

- Pilot, clinical trial material and commercial-scale manufacturing

- Comprehensive microbiology testing

- cGMP batch sizes from <500ml to 50l

- Controlled substances Schedule II – V

- Packaging capabilities for sterile dosage forms

- Micro-dose vials

- Tubes

- Unit-dose and bi-dose nasal sprays

- Vials

At Confab, we combine infrastructure with teams of scientists who have an in-depth understanding of solids, semi-solids and liquids that is backed by decades of experience. It is this combination of people and infrastructure that sets us apart from other CDMOs.

Our main goal and market activities are in Canada and the United States. However, we also serve customers that market their products in South America, Europe and several Asian countries.

Confab offers a wide variety of manufacturing capabilities, including core centered tableting, tablet dry coating, granulation, tablets and hard shell capsules, several types of coating, creams, gels, ointments, nasal sprays, syrups, suspensions, liquids and suppositories.

Solid dose manufacturing capabilities

Our solid dose manufacturing capabilities include:

- Powder blending

- Standard granulation

- High shear granulation

- Powder compaction

- Tableting

- Tablet coating

- Encapsulation

- Double encapsulation

- Tablet printing