Fujifilm Diosynth Biotechnologies is one of the world’s leading providers of contract process development and manufacturing services for the biopharmaceutical industry.

Formed in April 2011, the company has more than 900 employees operating from two sites in Billingham, UK, and Research Triangle Park, North Carolina, US.

Together we have more than 15 years of experience working with over 230 complex proteins, and both sites have been successfully FDA inspected for the manufacture of commercial products, demonstrating our strong track record in navigating the critical path through validation and regulatory approval.

Over the last 12 months, we have announced additional mammalian cell culture capacity at both our RTP site (commissioned early 2012) and a new cGMP mammalian cell culture facility at our Billingham, UK site (commissioned Q3 2013).

A ‘one-stop-shop’ is available for antibody drug conjugate (ADC) development through our alliance with Piramal Healthcare. The combined ADC development between Fujifilm and Piramal ensure rapid conjugation demonstration and route to market.

Biologics process development

As a full-service contract manufacturer, we offer an extensive breadth of process development capabilities to meet our customers’ needs at every stage of the product lifecycle.

Our experience ensures process development is applied appropriately, dependent upon the development needs of customer products at different clinical stages.

We offer:

- A wide range of constructs and expression options including development of a customer’s existing system or creating one de novo from our family of microbial therapeutic protein production systems, including our pAVEway system

- Microbial capability in the development laboratories include multiple 5l, 15l and 140l fermenters

- Mammalian cell line development capability

- Mammalian capability in the development laboratories include multiple 2l, 5l, 10l, 15l, 20l and 110l bioreactors, wave 20/50, and 2 x 200l Xcellerex systems

- 100l scale pre-cGMP pilot plant for process demonstration and supply of pre-clinical material

Biologics cGMP manufacturing

At our sites in Billingham, UK, and Research Triangle Park, NC, US, we offer a broad range of mammalian and microbial cGMP manufacturing capabilities. We employ protocol-driven technology transfer processes to bring in projects from customers and seamlessly integrate them into these facilities. Our facilities have received successful regulatory inspections from all key regulatory agencies.

Microbial:

- Various scales for rapid cGMP manufacture of material for Phase I-III clinical supply, process validation and commercial supply from 100l to 5,000l

- Flexible plant configurations including disposables technology and refold volumes of up to 10,000l

Mammalian:

- 2 x 110l and 1 x 2,000l train (20l,145l, 650l) for cGMP manufacture of material for Phase I-III clinical supply, process validation and commercial supply

- 1 x 1000l single-use bioreactor at RTP site; 1 x 200l and 1 x 1,000l single-use bioreactor at Billingham site; 1 x 2000l single-use bioreactor planned for 2014 at Billingham site.

Biologics manufacturing support services

The following additional services are offered to reduce complexity and risk of multiple suppliers:

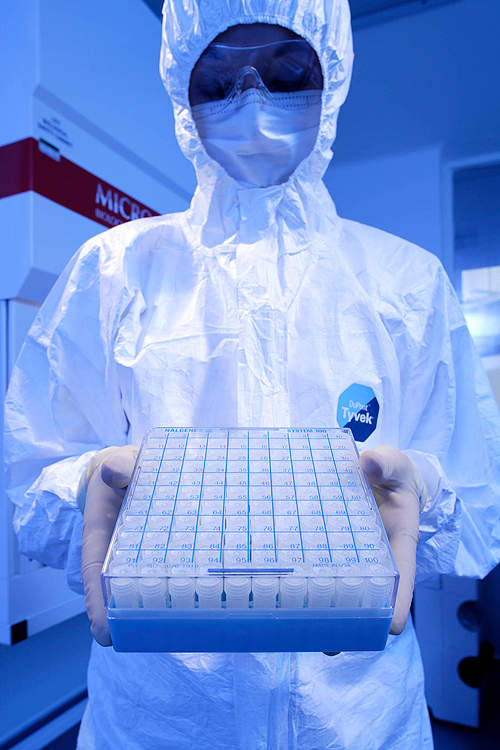

- cGMP cell banking facilities for production of master and working cell banks

- Buffer screening studies to support downstream process development

- Development of stable product formulations

- Full range of in-house analytical methods

- Full range of stability testing capabilities for drug substance and drug product

Quality and regulatory support for biopharmaceutical development and manufacturing

Our aims include:

- To ensure our customers’ products meet international regulatory requirements, we provide all the necessary quality and regulatory support through an independent quality unit

- Regulatory support for IND / CTA submission, DMF and CMC as required

- QC analysis and release of raw materials, environmental and water in-process / final, sample retention

- Ownership and use of qualified or validated methods

- Quality agreement followed by routine interactions with customer throughout the programme

Antibody drug conjugation

We can also offer a ‘one-stop-shop’ for antibody drug conjugates through our alliance with Piramal Healthcare. Through our rapid delivery of ADC drug substance, simplified supply chain and aligned mAb and ADC programmes the benefits include:

- Early transfer of material from Fujifilm to Piramal: rapid demonstration of conjugation

- Transfer of analytical methods from Fujifilm to Piramal

- Integrated programme management teams