Kemwell is a contract development and manufacturing organisation serving the pharmaceutical industry, offering both small and large module production, development, and global distribution.

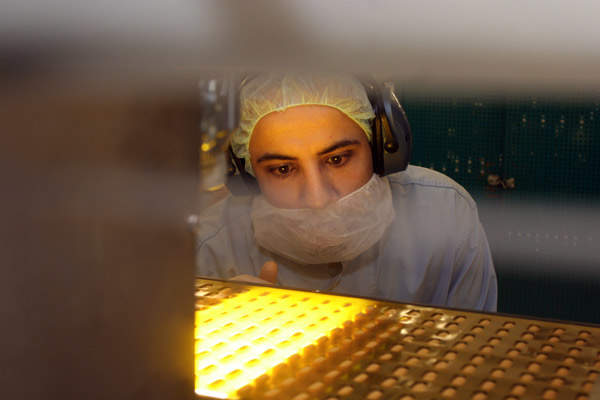

Kemwell’s scientists have strong experience in dosage form development, including parenteral, topical, oral, nasal, and inhaled. Its sterile and non-sterile product portfolio ranges from pre-formulation to worldwide commercial supply. Kemwell is approved by the European Medicines Agency (EMA), Therapeutic Goods Administration (TGA), Food and Drug Administration (FDA), Pharmaceuticals and Medical Devices Agency (PMDA), Medicines and Healthcare products Regulatory Agency (MHRA), and the Medicines Control Council (MCC).

With ten facilities in India, Sweden and the US, Kemwell’s workforce of 1,200 serves more than 100 clients from the pharmaceutical and biopharmaceutical sectors. In 2006, Kemwell acquired a site in Uppsala from Pfizer. It also later acquired product development organisation Cirrus in 2013, which allowed for global collaborations, providing manufacturing, product development, and task-based services.

EU gateway release testing

The majority of dose forms Kemwell offers today are solid dose tablets; uncoated, sugar-coated, and film-coated (solvent and aqueous) tablets; suppositories; effervescent and bi-layer tablets; hard gelatin capsules filled with powder, granules, pellets, or liquid-orals; semi-solid creams, gels, and ointments; and controlled and psychotrophic drug substances.

The company’s common biopharmaceutical facility (15,000m²) for large molecules in Bangalore offers services such as full-service process development, manufacture, formulation, and fill / finish. The current good manufacturing practice (cGMP) production facility is a one-stop-shop, with access to large-scale commercial production.

Drug formulation development, stability studies, clinical batch production and manufacturing

Kemwell has the experience, expertise, and infrastructure in place to meet your every need. Discover how these development and manufacturing solutions can keep you competitive. They include:

- Kemwell guarantees the high standards of quality and compliance, so you can benefit from high customer service levels

- Reduce time between drug development and commercialisation, shortening lead times for an efficient supply chain

- Do more with less in research and development (R&D) and manufacturing, innovate to streamline manufacturing

Whether you are looking for pre-formulation studies, formulation development, stability studies, analytical support, clinical batch production, commercial-scale manufacturing, or packaging, Kemwell is the ideal partner for you.

Through collaboration and innovation, Kemwell meets every challenge successfully, refusing to rest until the customer is satisfied.

Pharmaceutical process facilities

Kemwell’s Swedish facilities have more than 50 years of experience in supplying pharmaceutical products. The company’s core process technologies include wet and dry granulation, compaction, blending, and high shear mixing, as well as fluid bed drying, tablet pressing, capsule filling, semi-solid moulding, coating, and vision inspection.

Qualified person (QP) release services for pharmaceutical products

We also provide qualified person (QP) release services for Europe for products manufactured either at Kemwell’s site or outside the EU, covering the full chain of quality assurance (QA) responsibility for API and finished products. We have been inspected by the US FDA, EU, and Japanese regulatory authorities and supply to more than 80 markets worldwide.

Spread over 14,000m², Kemwell’s Swedish facilities are capable of expanding and adapting quickly to meet the high demands of the customer.

Oral solids, liquids and semi-solids facilities

Kemwell’s new oral solids facility is a state-of-the-art building in Bangalore. It manufactures up to five billion tablets and capsules for global supply, covering more than 15,000m². The facility has been designed to marry flexibility with stringent measures for contamination control.

Kemwell’s liquids facility has been supplying to customers since 1995 and has benefited from continuous investments in process improvements and expansions. The compans ais building a new liquids facility to increase its manufacturing capacity.

Kemwell’s semi-solids facility has been in operation since 2001. The company manufactures gels, ointments, creams, and solutions for various topical and ophthalmic applications.

- Blisters: ALU-PVC, ALU-PVC/PVDC, ALU-Aclar, ALU-ALU, ALU/PE-ALU/PE, ALU-Triplex (COC/PVC/PVDC)

- Containers: glass bottles, plastic bottles, aluminium, and plastic tubes

- Sachets / pouches

- Blister packing including child-resistant packs

- Bottle packing in various sizes with CRC, press-fit and screw capping capability

- Controlled and psychotropic drug substances can be handled

Quality contract manufacturing, development services, packaging and global distribution

Kemwell meets current good manufactruing practices (cGMP) as per international quality guidelines, which ensures that all products meet the highest quality standards. We continue to invest in people, processes and equipment to ensure that Kemwell remains a quality leader in every aspect of its business and that quality is the foundation of its success.

Our quality policy is:

- To apply the principles of quality assurance to all activities and systems, with continuous evaluation and improvement with a view to achieve consistent standards of quality

- To ensure that all personnel in the organisation are committed to maintaining corporate and customer quality requirements in every aspect of business

- To comply with all statutory regulations of the local authorities as well as those applicable to all markets to which the products are being supplied, to ensure that quality is the foundation of our success