Established in 1987, PBSC has become one of the leading manufacturers of Clean Room, High Containment and Material Decontamination products throughout the world.

History – With an extensive product range, bespoke designs and assembly capabilities, PBSC has grown over the years to meet customers’ needs with high-quality products and services within the Pharmaceutical, Medical Research, High Containment and Hospital sectors around the world.

Vision – The search for innovative designs, an eye for detail and advanced manufacturing techniques has seen PBSC gain a deserved reputation as the premier supplier within cleanroom environments.

Committed to providing customers throughout the world with safe, accurate, quality products and services, PBSC ensure the undue risk of contamination.

Logistical

Having agents and representatives in many countries around the world, allowing PBSC to deliver excellent local support and logistical services to make sure your products arrive on time including dispatching major spare items at short notice.

Products

Complying with local and global regulations PBSC’s products can be designed to meet your specific requirements. With over 30 years knowledge and competence within the specialist sectors, always going through extensive research and development and offering accurate assistance during project planning to consultants, architects and end-users to help improve and save people’s lives.

Our products include:

- Decontamination Chambers and Hatches

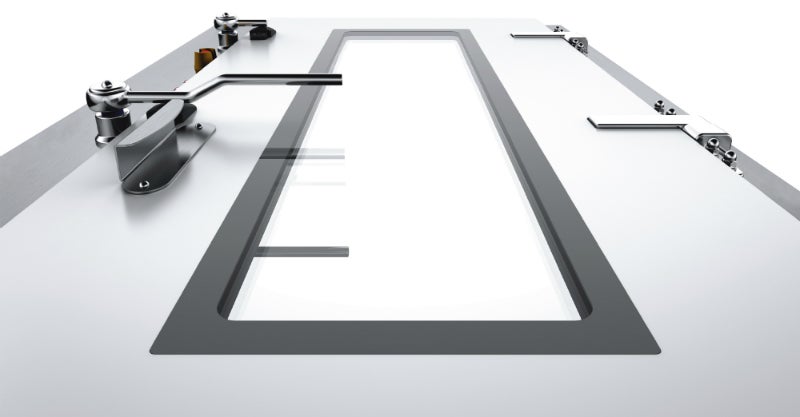

- Inflatable and Mechanical Seal clean room doors

- Classic Steel and Glass clean room doors

- Phenolic Resin clean room door sets

- Emergency Escape Panels

- Fogging and Air Showers

- Transfer Hatches and Pass Throughs

- Vision Panels

- Dunk Tanks

Quality

PBSC is committed to delivering high standards to customers by anticipating their needs, offering reliability that exceeds expectations.

Supporting the customer throughout the process continuing to meet the growing challenges and striving for continual improvement with QA processes independently audited and updated on a regular basis and as an ISO9001 accredited business PBSC brings quality to the center of each and every product and service they offer.

Sectors

- Pharmaceutical

- Medical Research

- Hospital Sectors

- High Containment

- Clean Rooms

R&D

PBSC’s culture is of innovation of continual improvement and development across the product range.

Research and Development is driven by market demands to ensure the products meet client requirements, with a reputation for improving and providing first-to-market products that make PBSC the industry leader, spending time researching and developing new technologies and performance towards offering the best commitment and service possible to the customer.

The research and development processes are constantly progressing with large levels of investment.

Safety and verification are also important values for PBSC and a lot of in-house testing is conducted to ensure the reliability and durability of our products.

Over the years, as our products have grown more complex and with more sophisticated control options, there is a growing need for end-user training.

PBSC offers training when required by the customers and our worldwide distribution network.

We encourage our customers to take advantage of the operator training which we can offer at our PBSC offices or onsite.

Having your technicians properly trained saves time and money whilst keeping your controlled environments running smoothly and safely.

Architecture

The PBSC clean room door sets, transfer hatches, pass-throughs and vision panels within our architectural range are specially designed for use in cleanroom applications, in particular, hygienic or controlled environments and are widely used within facilities with frequent traffic and where air leakage cannot be permitted, possessing high durability, minimal visible fixings, flush designs and excellent scratch/wear resistance.

Personnel Decontamination – PBSC’s fogging and air showers are used to clean personnel on entry or exit for high containment areas to remove traces of possible contamination from protective garments. PBSC has extensive independent third-party testing on the efficacy of our fogging showers for specialist API facilities.

A wide range of customized designs are available to meet most customers’ requirements.

High Containment

PBSC provide equipment designed and tested for the highest levels of containment. With references in many leading BSL3 and BSL4 institutes. We offer a range of products which create a dependable barrier using strong but flexible solutions where high containment is required. PBSC has developed a full range of equipment to suit all applications from BSL2 to BSL4, including specific designs to work with various building wall constructions.

Material Decontamination

PBSC’s chambers and hatches are effective against a wide range of decontamination needs, coming in various sizes. With the extensive development of the product range PBSC can provide a vast range of options to ensure a chamber will meet a client’s facility needs, including industry-leading automation integration for Pharma facilities.

The chambers can be provided in smaller pass-through units from 1m³ to large 40m³ chambers.

Providing validated, repeatable cycles with GMP compliant monitoring to ensure successful cycles and operator safety.

Cycle times from 35 minutes with Log 6 kill.