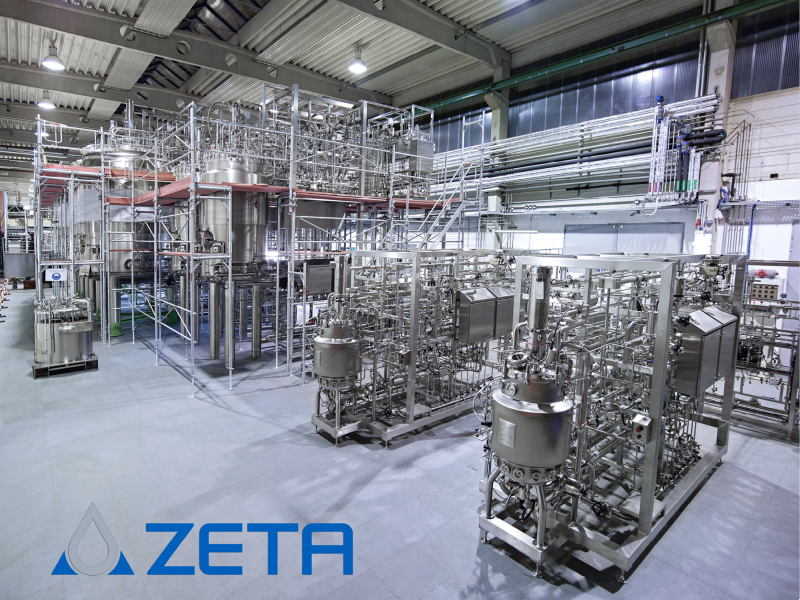

The ZETA Group is an end-to-end solution provider operating globally and specialising in the design, construction, automation, digitalisation and qualification of customer-specific biopharmaceutical systems for aseptic process solutions.

From lab to fab: GMP-compliant scaling

The path of newly developed active substances in the lab into the preclinical phase and in early clinical GxP production, followed by scaling of the manufacturing process to industrial scale, through to market introduction in secure routine operation at the production facility is a complex and challenging process for the pharma and biotech industry. ZETA accompanies this entire active substance development and manufacturing process with comprehensive services and offers solutions for the construction, scaling and upgrade of production equipment.

Continuous improvement

ZETA provides support after commissioning of the process equipment through targeted ramp-up as well as service and maintenance along the entire product lifecycle. True to the principle of continuous improvement, ZETA guides customers during process and system optimisation as well as operator training. ZETA’s aim is to achieve a 100% batch success rate.

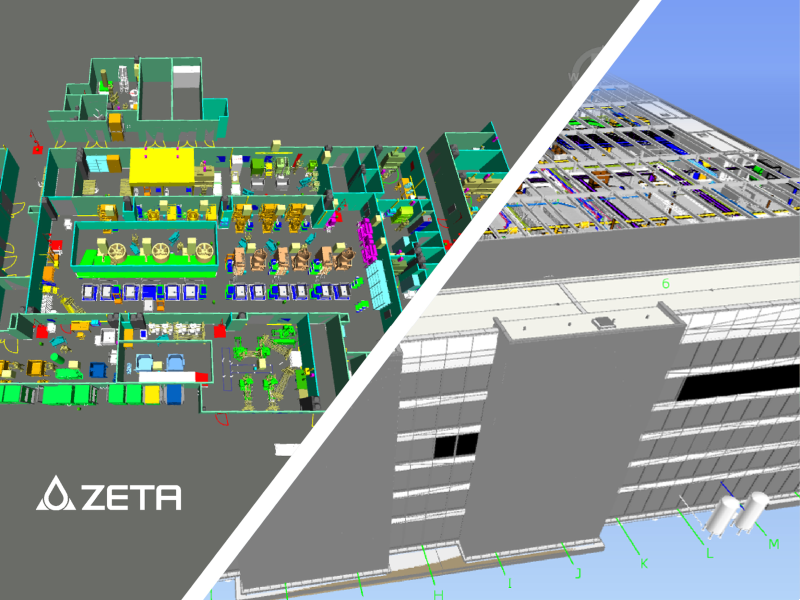

Time to market – up to 50% faster

As EPCM contractor, ZETA manages major, high-complexity pharma projects and specifically reduces interfaces—from the planning and construction of the process system through the cleanroom design up to the technical building infrastructure.

This design-build approach accelerates the project execution time by up to 50% and leads to creation of value earlier in the customer’s capex projects. In doing so, ZETA provides an active contribution to the rapid market introduction of vital active ingredients and patients benefit from earlier availability of pharmaceuticals such as anti-cancer medications, insulin and vaccines.

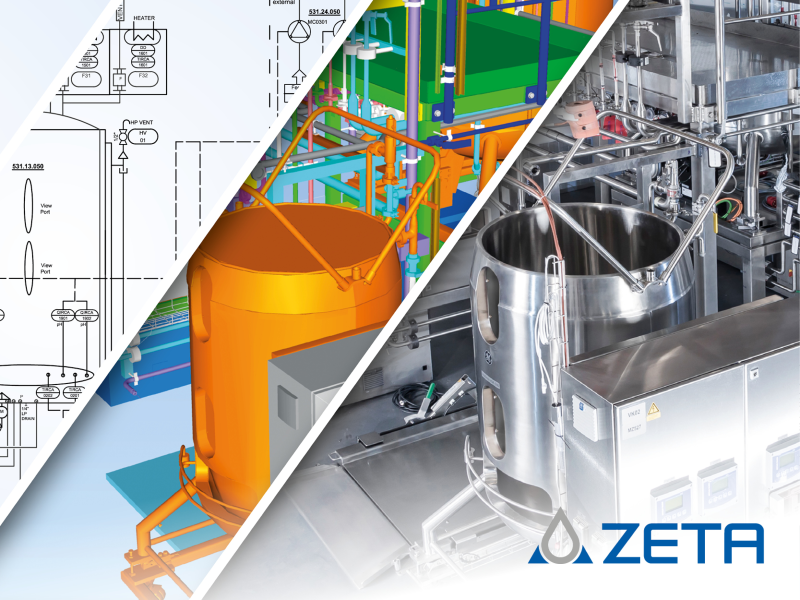

Fully integrated digital value chain

In the field of digitisation, ZETA’s fully integrated digital value chain—from engineering through qualification and operator management—has established the company as an innovation driver in the pharma and biotech industry.

Together for a sustainable future in the pharma and biotech industry

ZETA is also actively taking steps towards a more sustainable future for the entire industry: Holistic decarbonisation strategies that reduce targeted emissions during the biopharmaceutical manufacturing process are integrated with sustainable energy sources for the power supply of the entire infrastructure and investment scenarios in renewable energy are evaluated using profitability calculations.

Your reliable partner for pharma and biotech projects:

- EPCM contractor

- Plant engineering

- HVAC, cleanroom and BMS/EMS design

- Automation

- Digitalisation

- Qualification

- Maintenance and upgrades

- Research & Development

- Decarbonisation strategies